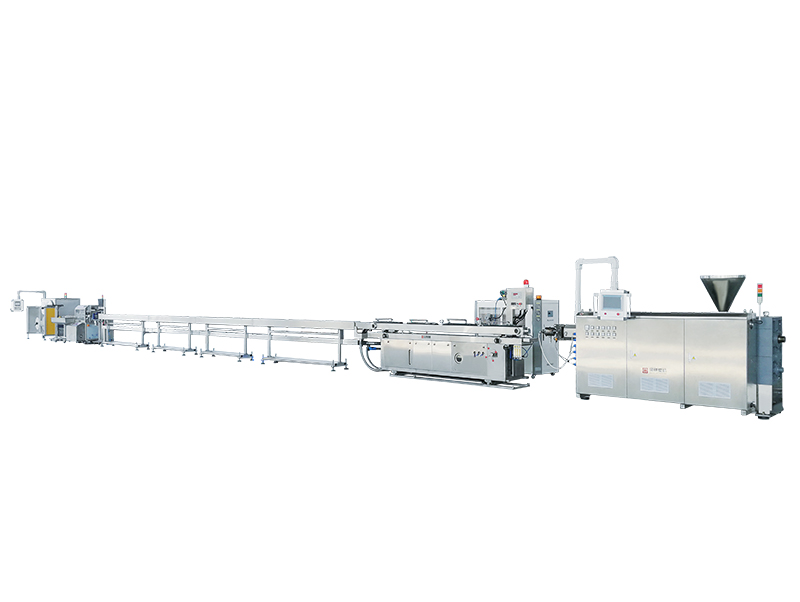

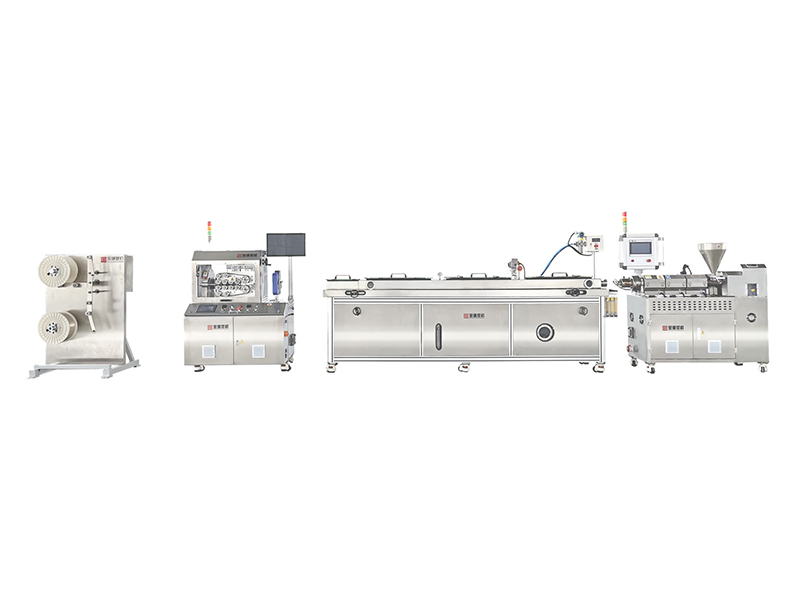

Iimpawu zeZixhobo

-Umgca wemveliso ozenzekelayo ophezulu oxhotyiswe ngokukodwa owenziwe ngokukodwa wokufuduswa koxinzelelo oluphezulu uqinisekisa ukugqithiswa okuchanekileyo, okuzinzileyo kunye nesantya esiphezulu;

- Ngeteknoloji entsha yokulawula i-vacuum: i-vacuum kunye nenkqubo yamanzi ilawulwa ngokwahlukileyo. Ngale ndlela, sinokulungelelanisa inkqubo yokulawula ukulingana kwamanzi amanqanaba amaninzi kunye nenkqubo yokucoca, ukuqinisekisa iqondo elizinzile le-vacuum, inqanaba lokupholisa kwamanzi kunye nokuhamba kwamanzi;

- Inkqubo yokulinganisa i-BETA Laser, ukwenza ulawulo lwengxelo evaliweyo, ukuphelisa ukutenxa kwi-diameter kwi-intanethi;

-I-Puller ixhotyiswe ngebhanti ye-synchronous-layer-layer-resisting, ngaphandle kwe-sliding phenomenon. Inqanaba eliphezulu lokuchaneka kwe-roller drive traction, inkqubo yokuqhuba ye-YASKAWA Servo okanye inkqubo yokuqhuba ye-ABB AC, qonda ukutsalwa okuzinzile kakhulu;

- Ngokusekelwe kwinkqubo yokuqhuba i-Servo, iJapan Mitsubishi PLC yolawulo olucwangcisiweyo kunye ne-SIEMENS i-interface yekhompyutheni yomntu, i-cutter inokuqonda ukuchaneka ukusika okuqhubekayo, ukusika ixesha, ukusika ukubala ubude, njl.

Yethuinzuzo

IParameter yobuGcisa engundoqo

| Umzekelo | Inkqubo yoluhlu lwedayamitha yombhobho (mm) | Idayamitha yesikru (mm) | L/D | Amandla aphambili(KW) | Isiphumo(Kg/h) |

| SXG-30 | 1.0 ~ 6.0 | 30 | 28-30 | 5.5 | 5-10 |

| I-SXG-45 | 2.5–8.0 | 45 | 28-30 | 15 | 25-30 |

| SXG-50 | 3.5-12.0 | 50 | 28-30 | 18.5 | 32-40 |

| SXG-65 | 5.0-16.0 | 65 | 28-30 | 30/37 | 60-75 |

| SXG-75 | 6.0-20.0 | 75 | 28-30 | 37/45 | 80-100 |

Ukucaciswa kweTubhu encinci yePe / Pp kunye neReferensi yobume beMveliso

| OD(mm) | Ukuvelisa isantya(m/min) | Ukuchaneka kolawulo lwe-diameter(≤mm) |

| ≤4.0 | 65-120 | ±0.04 |

| ≤6.0 | 45-80 | ±0.05 |

| ≤8.0 | 30-48 | ±0.05 |

| ≤10.0 | 23-32 | ±0.08 |

| ≤12.0 | 18-26 | ±0.10 |

| ≤16.0 | 10-18 | ±0.10 |

Ukusika Ukuchaneka Reference

| Ukusika ubude | ≤50mm | ≤400mm | ≤1000mm | ≤2000mm |

| Ukusika ukuchaneka | ±0.5mm | ±1.5mm | ±2.5mm | ± 4.0mm |