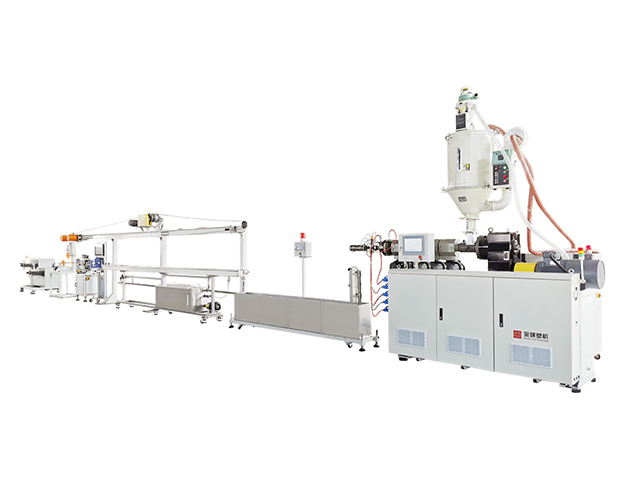

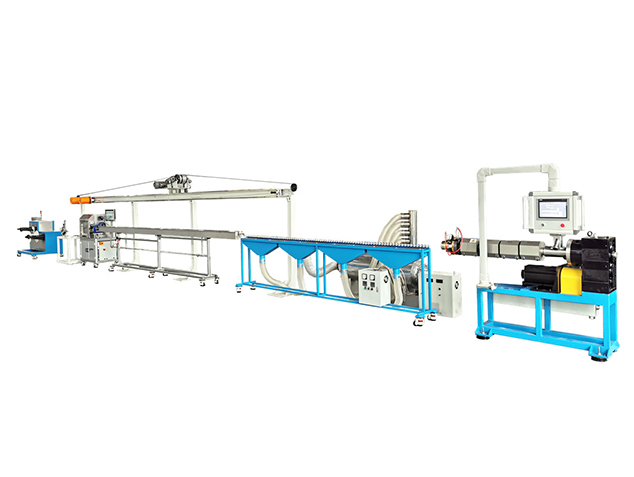

I-3D Printer Filament Extrusion Line (Ulungelelwaniso oluthe nkqo)

-

Isantya semveliso:

DN1.75mm 120-150m / min, DN3.0mm 45-55m / min.

-

Lawula ukuchaneka:

Φ3.0 mm ukuya kwi-2.9 mm, 1.70 ukuya kwi-1.80 mm. (Ubukhulu +/-0.04mm, i-Avareji +/-0.03mm, CPK≥1.6)

Ulwazi lweMveliso

Ubume be-3D yomshicileli weplastiki i-filament yintambo ejikelezayo eqinileyo okwangoku, eyona nto iphambili i-PLA, i-PVA, i-HIPS, i-ABS, i-PC, i-PA, i-TPU njl., iimveliso zivela kwi-1.75 mm ukuya kwi-3.0 mm ububanzi. I-BAOD EXTRUSION ibonelele ngeseti yokuqala ye-3D PRINTER FILAMENT yomatshini wokukhupha kumthengi ngo-2009. Emva kwexesha elide lokuvavanya kunye nokuqinisekiswa, sifumene ukuba kwixabiso eliphezulu lokunyibilika kwezinto ze-polymer (ezifana ne-TPU, i-PA, i-PC, njl.) ngokuthe nkqo. inkqubo yokupholisa ukulinganisa, ubungakanani bokubumba (ingakumbi i-ellipticity) ye-filament iye yaphuculwa kakhulu. Ukulungelelaniswa kwenkqubo ye-3D yomshicileli we-filament extrusion kwizinto eziphathekayo iyandiswa ngakumbi.

Yethuinzuzo

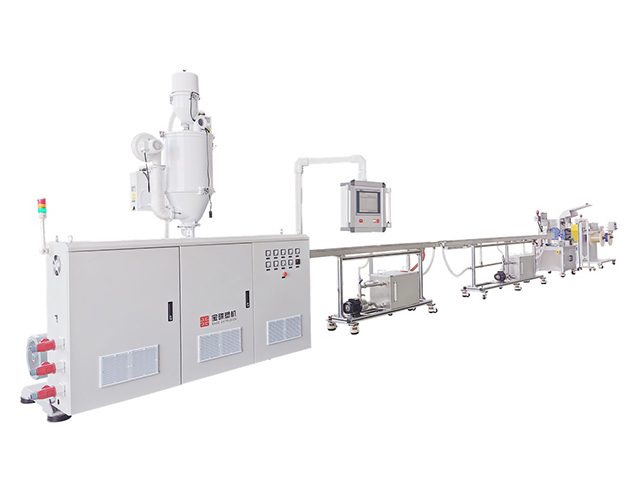

Iimpawu zoMshini woMshini

1. Ukuqhuba i-servo epheleleyo kuxhotywe kumgca womatshini opheleleyo, kukhokelela ekusebenzeni okuzinzile okuphezulu kwiindawo nganye kumgca we-extrusion, njenge-melt extruding, i-melt metering, ukudonsa, njl.;

2. Ukuxhotyiswa ngenkqubo yempompo yokulinganisa, qinisekisa ngokuphindwe kabini ukuchaneka kokuhamba okunyibilikayo, okwangoku ukwandisa uxinzelelo lwentloko yokufa ukuze ugweme umngxuma ongaphakathi wocingo;

3. Ixhotyiswe nge-laser gauge ye-diameter ye-intanethi kunye nomsebenzi wokulawula impendulo yobubanzi obuzenzekelayo, lawula ukunyamezelwa komda kwixabiso elincinci, ukuphakamisa umgangatho we-automation yomgca wonke;

4. Ukujija kunye nokuHamba nge-SERVO drive & PLC ulawulo lweprogram ukuqonda ngokuchanekileyo kwi-intanethi kunye nocwangco (ucocekile) ukujija, ukujika okukhoyo kuzo zombini i-spool enkulu kunye encinci.